Rapid dispensing and consistent results make Uni-form industrial epoxy preforms the no-mix, no-mess solution to liquid dispensing problems. This simplified yet high-quality approach to epoxy sealing has been adopted by a wide variety of industries including automotive, aerospace, appliance, military, and medical.

Our epoxy preforms can be configured to accommodate components as diverse as switches, PCB connectors, fiber optics, fuse holders, LEDs, resistors, potentiometers, and EMI filters. And our variety of epoxy systems allows our seals to operate in diverse environments ranging from under-the-hood to underwater to outer space.

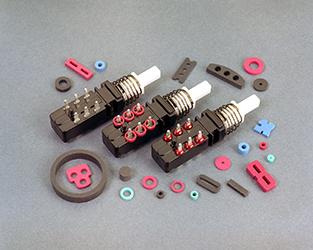

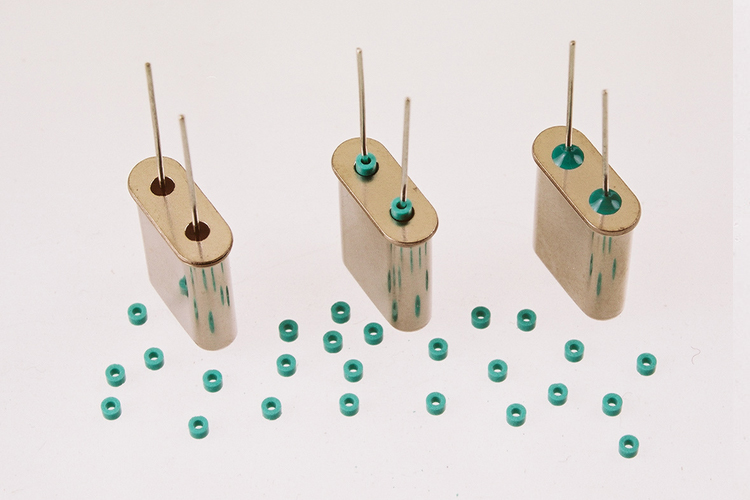

Switch manufactures worldwide have adopted Uni-forms for sealing terminals. Most switches are easily accommodated with automated loaders for rapid loading rates. MSI has a variety of configurations available to accommodate most common terminal designs.

Sample packs for common switch seal configurations are available.

Receive Samples

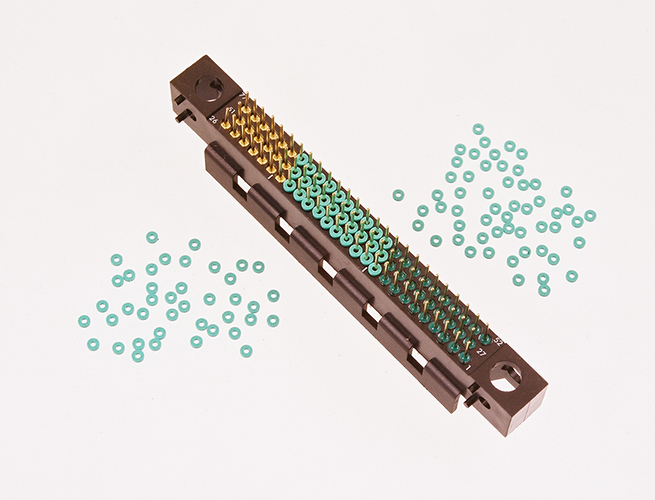

Connectors ranging from PCB, backplane, circular, coaxial, and D-Subs are easily sealed with Uni-forms. Most multiple-pin connectors are quickly and easily loaded with bowl-fed gravity tracks. Preforms eliminate unwanted epoxy drips on critical contact areas.

Sample packs for common switch connector seal configurations are available.

Receive Samples

EMI and RF filters are potted consistently and easily with Uni-forms.

Sample packs for common filter potting configurations are available.

Receive Samples

Uni-forms are available with IDs as small as .011″ to attach fibers to ferrules in fiber-optic connectors. Other configurations are available to attached ferrules to backbones. High-Tg systems are available to withstand the temperature and pressure of over-molding.

Sample packs for common fiber-optic seal configurations are available.

Receive Samples

Multi-Seals has formulated epoxy systems to protect electronic components from harsh under-the-hood conditions. Linear epoxies remain flexible to maintain seals on materials with different rates of thermal expansion during temperature extremes.

Uni-form epoxy preforms are also used to seal capacitors, circuit breakers, diodes, fuse holders, ink jet assemblies, LEDs, optoelectronics, potentiometers, resistors, sensors, transformers, fluid manifolds, and many more components. Please contact us to discuss the details of your application or receive samples or a free component evaluation.

We would like to learn more about your application. Please call (860)643-7188 or email sales@multi-seals.com today to discuss your requirements.

MADE IN USA