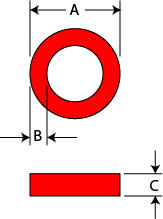

| FIGURE 1. - RINGS |  |

||

|---|---|---|---|

| "A" OUTSIDE DIAMETER |

"B" MINIMUM WALL THICKNESS |

"C" THICKNESS RANGE |

|

| 1.30~1.78mm | 0.51mm | 0.41~1.40mm | |

| 1.80~2.54mm | 0.51mm | 0.51~1.65mm | |

| 2.57~3.56mm | 0.64mm | 0.76~1.78mm | |

| 3.58~4.57mm | 0.76mm | 0.89~2.03mm | |

| 4.60~5.59mm | 0.89mm | 0.89~2.16mm | |

| 5.61~8.89mm | 1.02mm | 0.89~2.29mm | |

| 8.92~12.70mm | 1.14mm | 1.02~2.79mm | |

| "A" > 12.70mm CONSULT FACTORY | |||

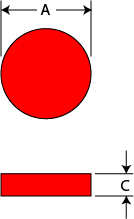

| FIGURE 2. - PELLETS |  |

|

|---|---|---|

| "A" DIAMETER |

"C" THICKNESS RANGE |

|

| 1.02~1.27mm | 0.25~1.27mm | |

| 1.30~1.78mm | 0.38~2.29mm | |

| 1.80~2.54mm | 0.51~2.54mm | |

| 2.57~3.56mm | 0.64~3.30mm | |

| 3.58~4.57mm | 0.89~3.81mm | |

| 4.6~8.89mm | 0.89~4.32mm | |

| 8.92~12.70mm | 1.02~4.32mm | |

| "A" > 12.70mm CONSULT FACTORY | ||